ABOUT

Gypsum is one of the most commonly used materials to date and prevalent in architectural acoustics. Everyday Acoustics explores a rethinking of applications for gypsum wallboard looking at folding designs and fabrication procedures which enhance its visual and acoustic properties. More specifically, the research investigates alternative design solutions for typical wall assemblies and their interior wallboard finishes to reduce harsh reflections of sound and enhance sound scattering.

The Everyday Acoustics project was funded by the 2021 Arnold W. Brunner of the New York Center for Architecture: The American Institute of Architects, New York Chapter and the Center for Architecture.

Project Team: Rachel Dickey, Arik Miguel, Hanieh Sotudeh Gharebaagh, Sierra Grant, Nathan Smith, and Sheriyth Cain.

RESEARCH

Contemporary architecture is known for producing buildings dominated by a proliferation of large, flat interior surfaces, which inherently allow for sound transfer and harsh reflections. In many cases, people both live and work in close proximity in these spaces. Therefore, architects need to consider the issue of acoustics when they design spaces for the everyday.

Unfortunately, incorporating sound-scattering materials and forms into contemporary architecture is generally viewed as a problem, when in fact it should be viewed as a design opportunity, in the same way that statuary coffered ceilings and relief ornamentation complemented classical architecture. Architects have generated many elegant solutions when designing spaces where acoustics play a central role, such as concert halls. However, such approaches have still not been widely or successfully applied to everyday spaces of domesticity and work. The designs of everyday spaces are often constrained by preconceived ideas of building materials and their traditional applications. For example, although gypsum wallboard could be implemented in a variety of creative ways in order to enhance both the visual appeal and the acoustics of a space, it is generally only added in layers or incorporated with sound attenuated batt insulation in an effort to help reduce sound leakage.

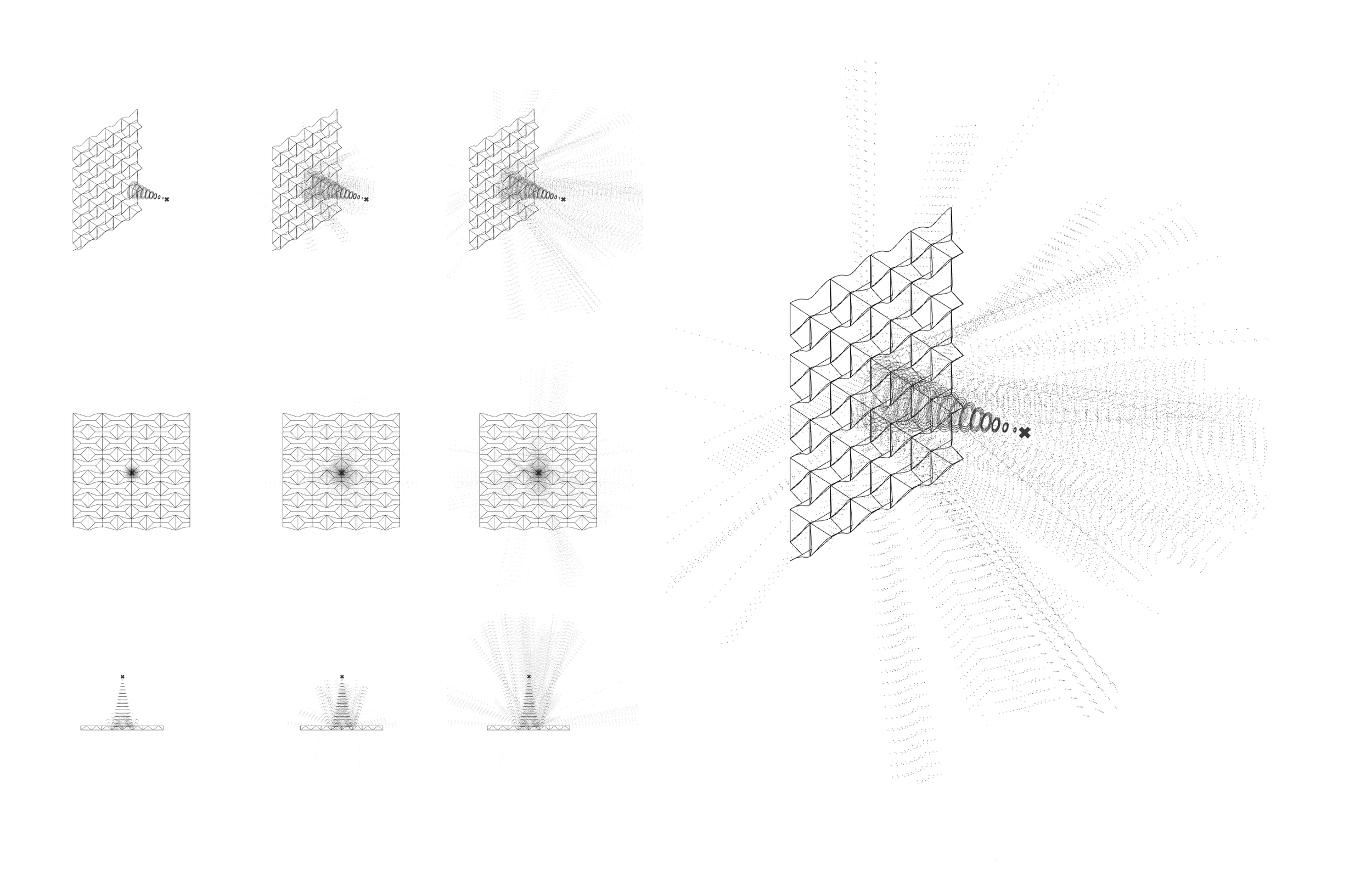

In this research catalog we have developed a set of alternative design solutions for typical wall assemblies and their interior wallboard finishes in a way that not only reduces transmission of noise and harsh reflections of sound, but also provides additional options for improving the visual quality of everyday spaces. The catalogue includes wall and ceiling designs, video demonstrations, and Revit wall system families that will both enhance acoustical performance and improve design of contemporary architectural spaces through the innovative application of gypsum wallboard finishes.

We the use traditional materials and assemblies with subtle changes in the final application of gypsum wallboard this research provides alternative surface designs, variations in form, and improvements in acoustical performance. The results of the research strive to enhance the architecture of the everyday by providing interior finish options that improve sound quality of space through novel design.

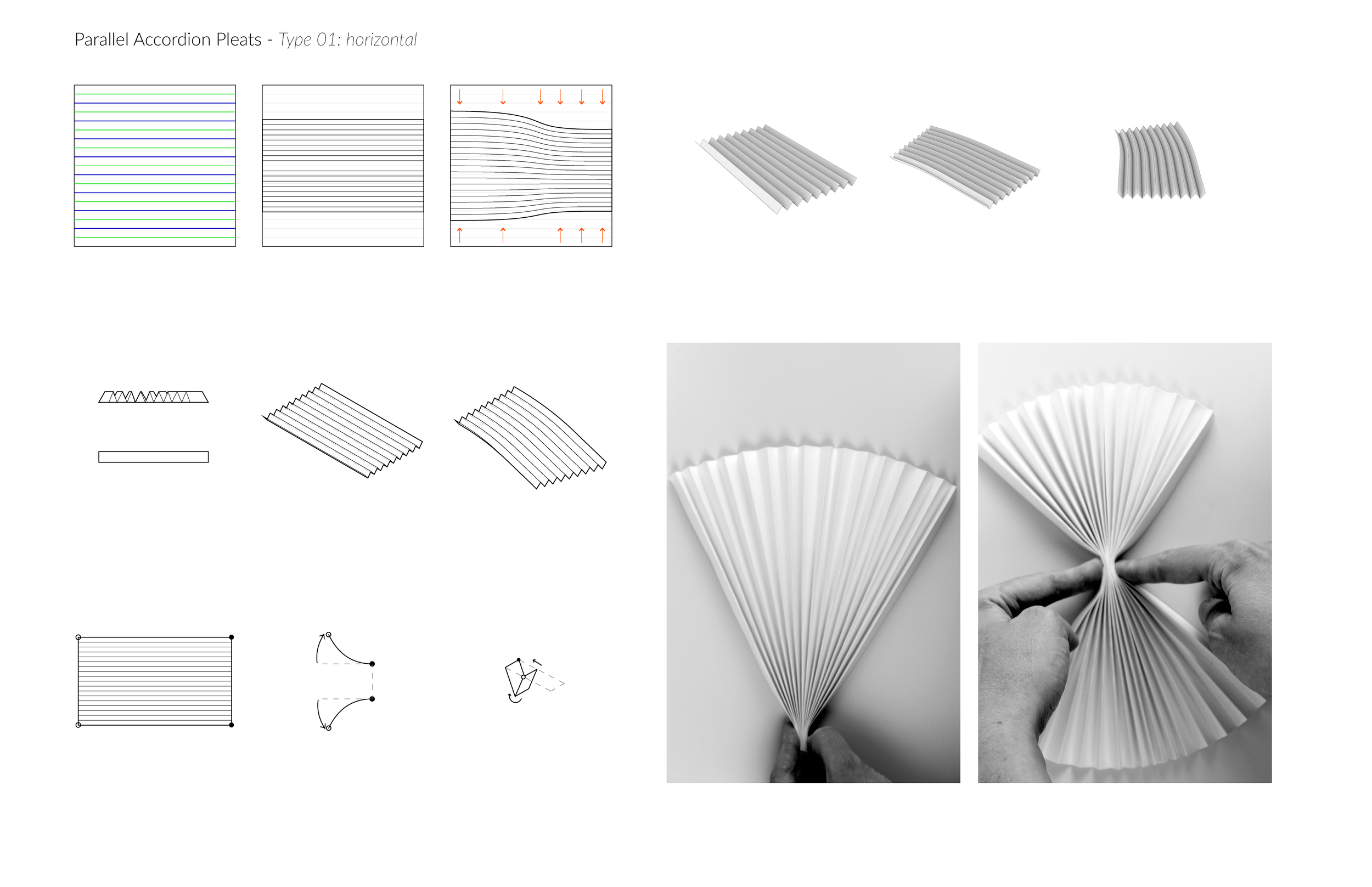

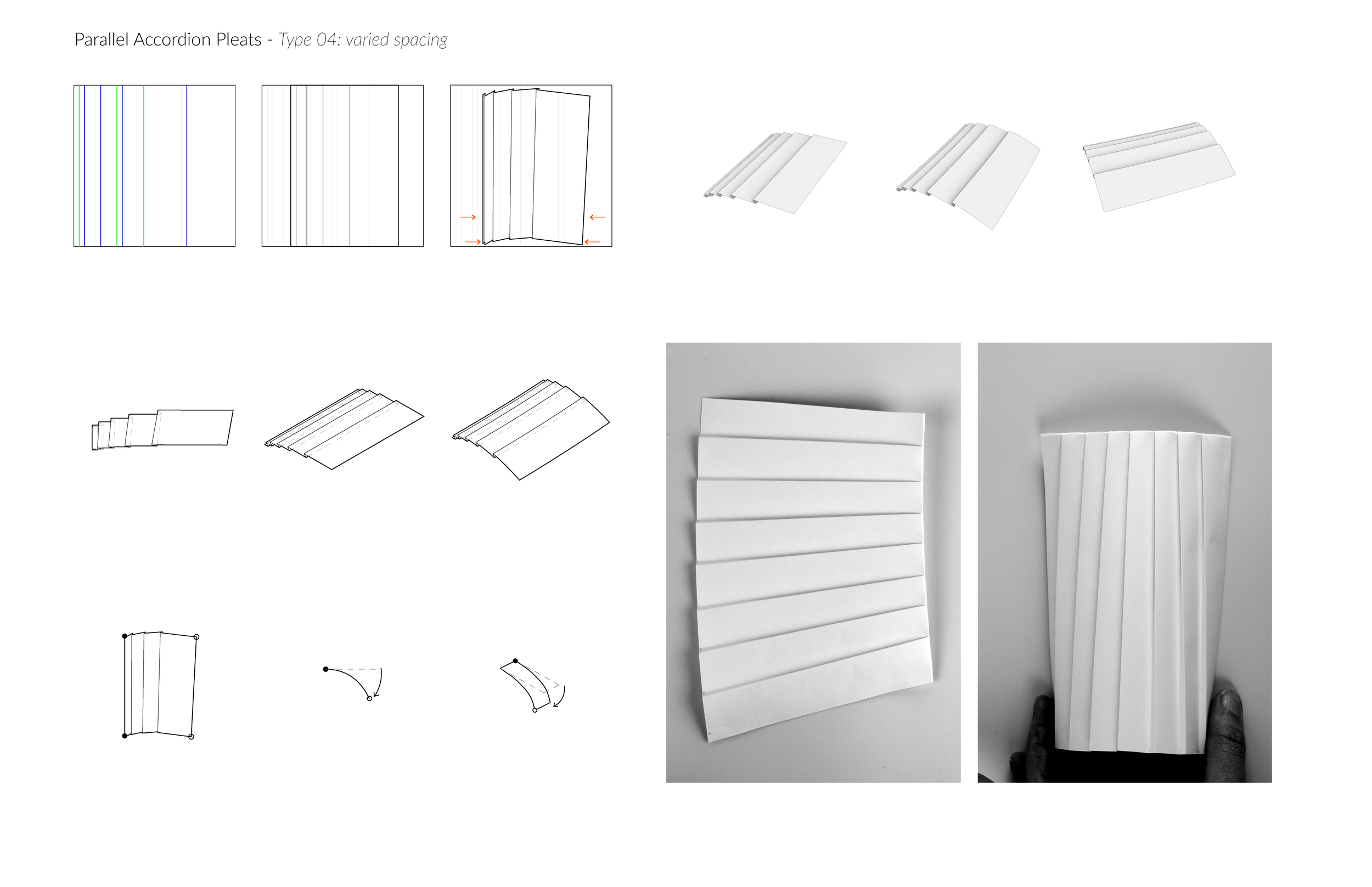

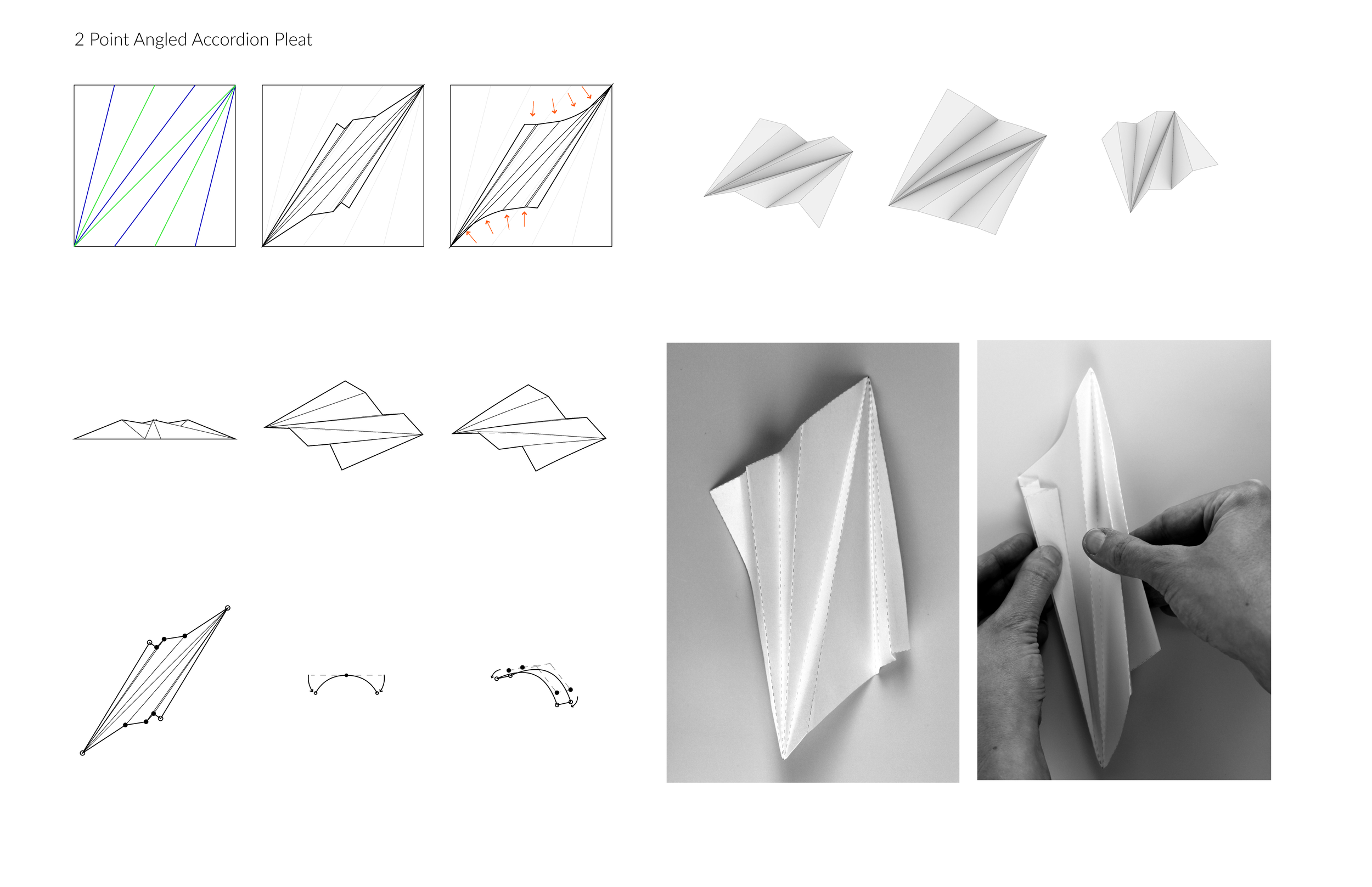

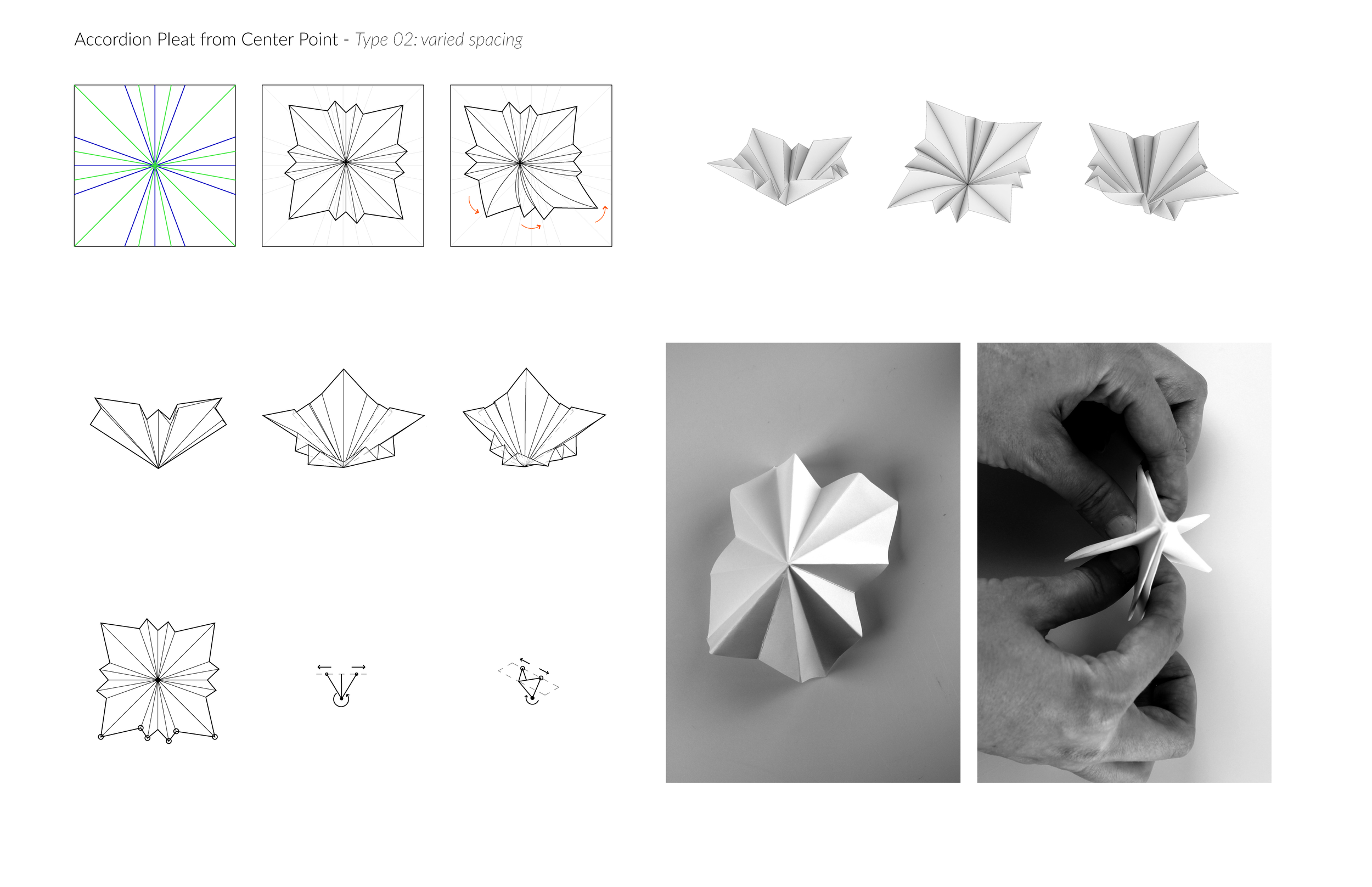

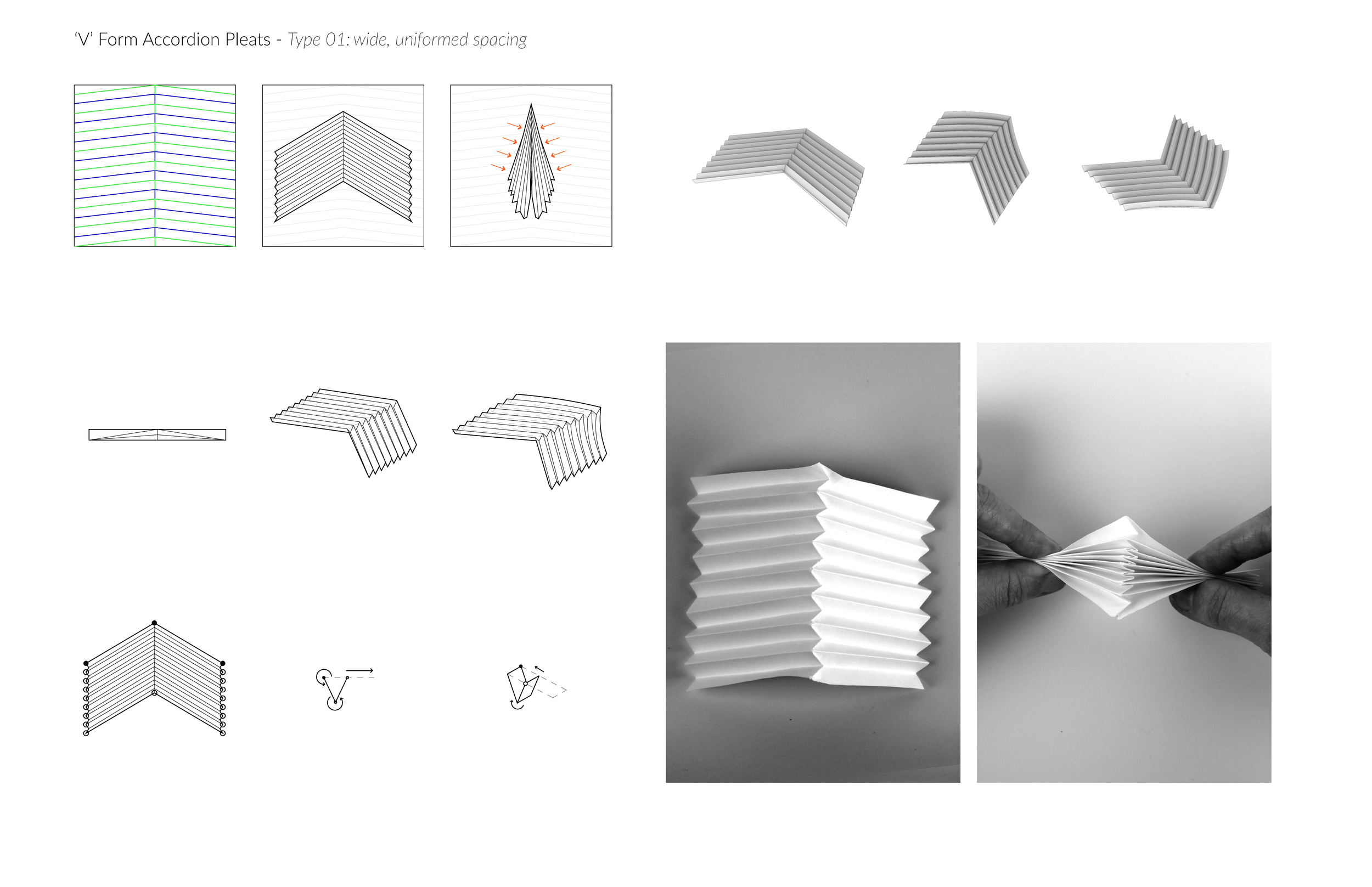

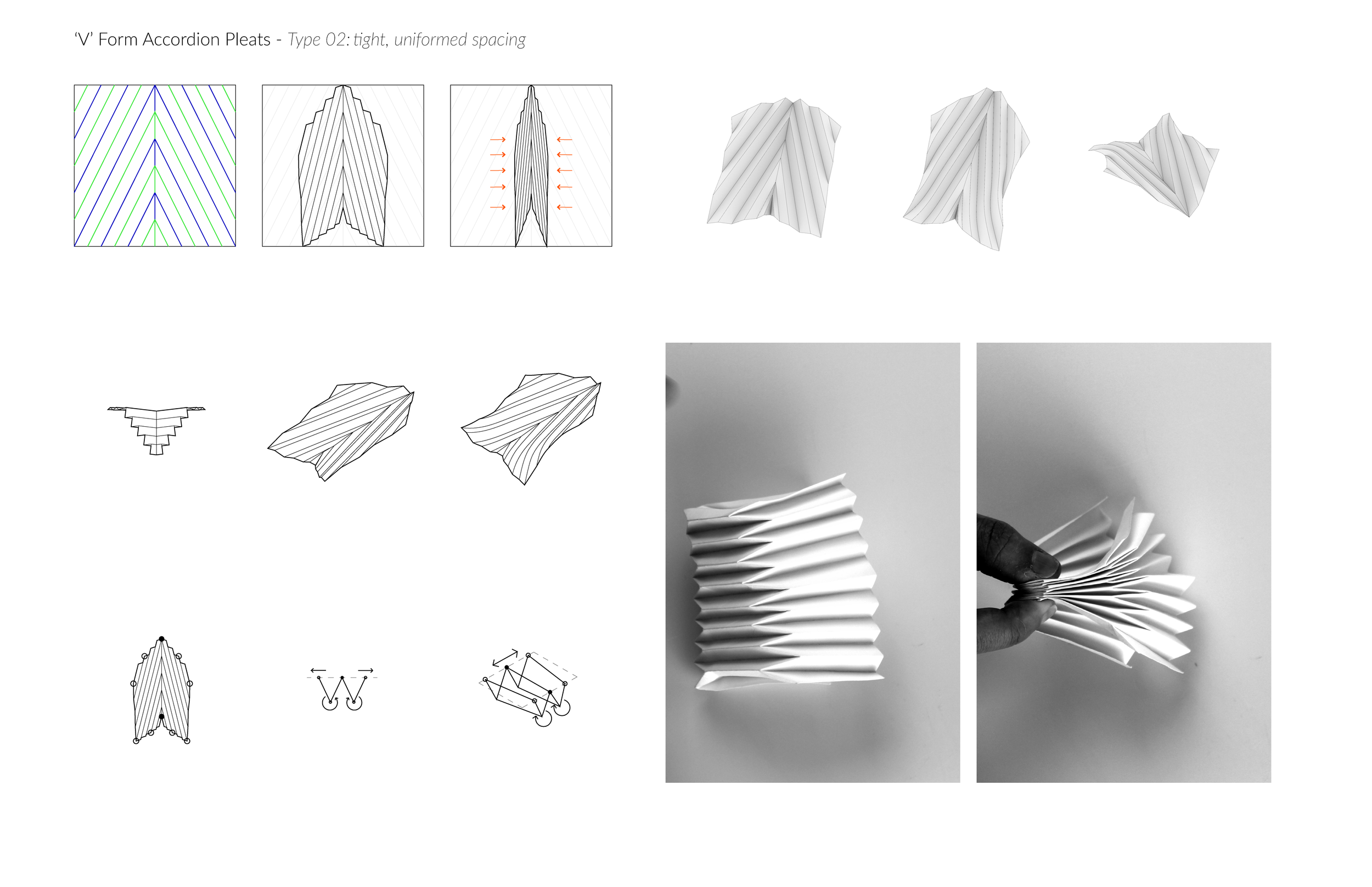

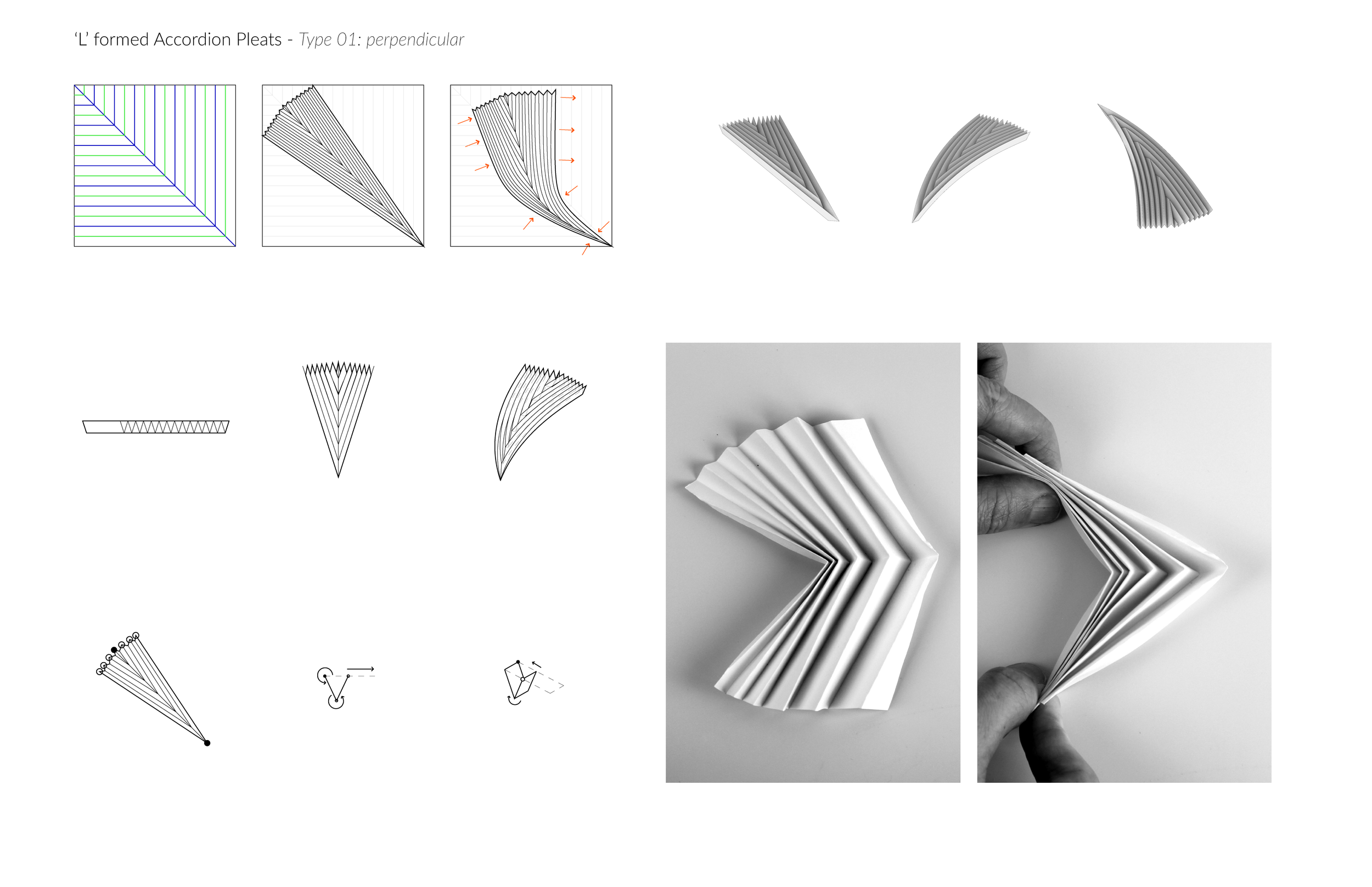

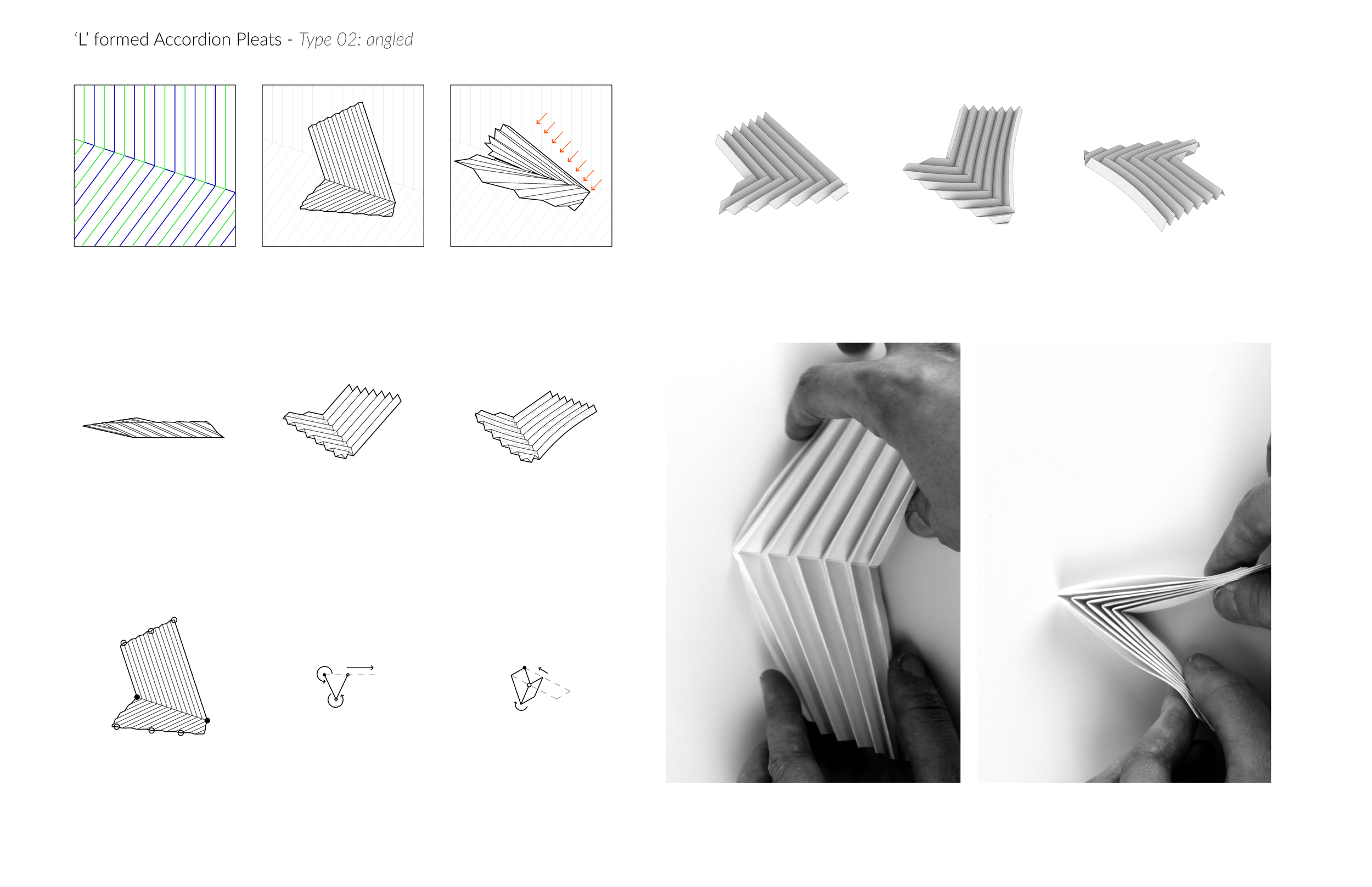

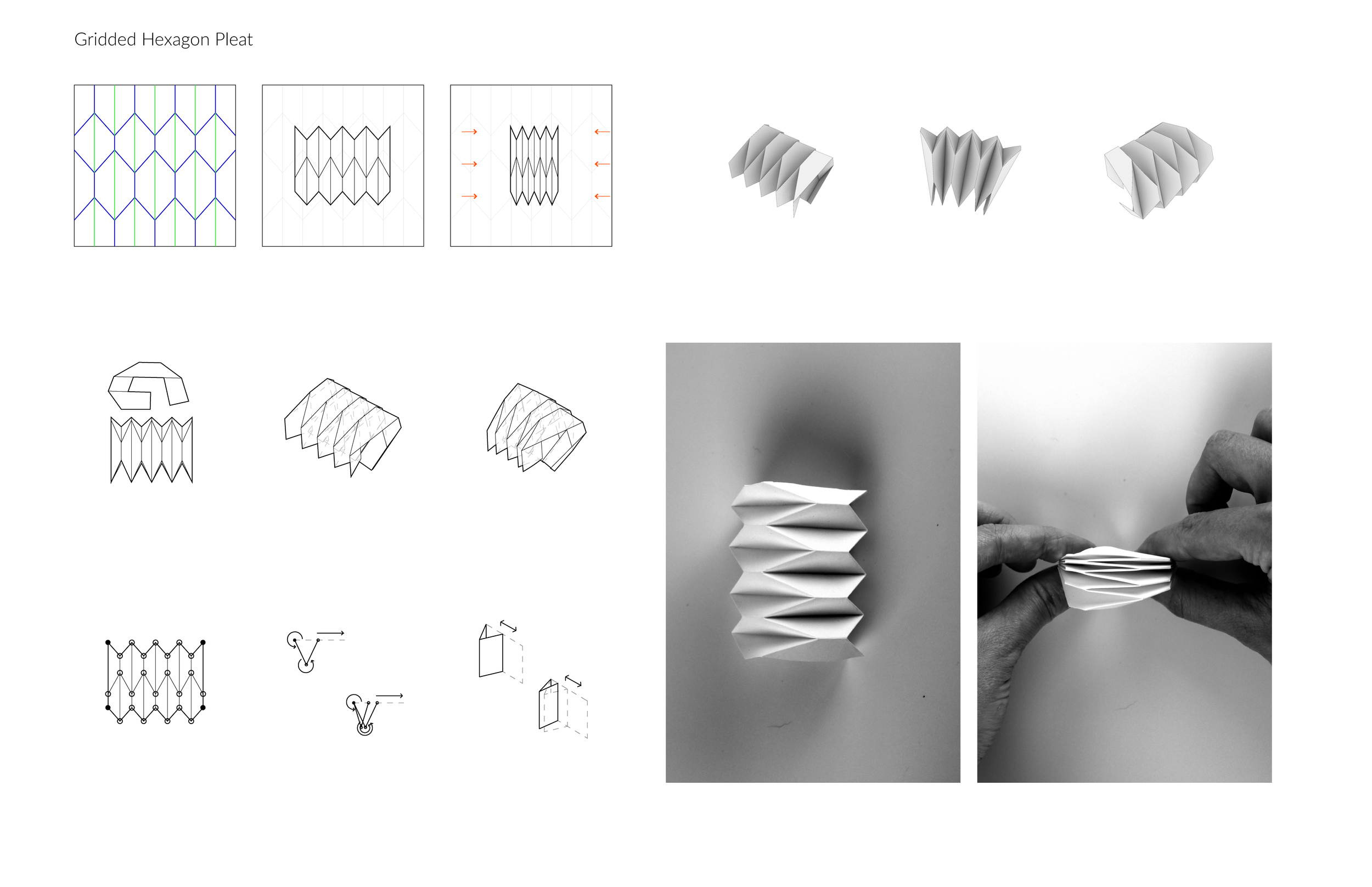

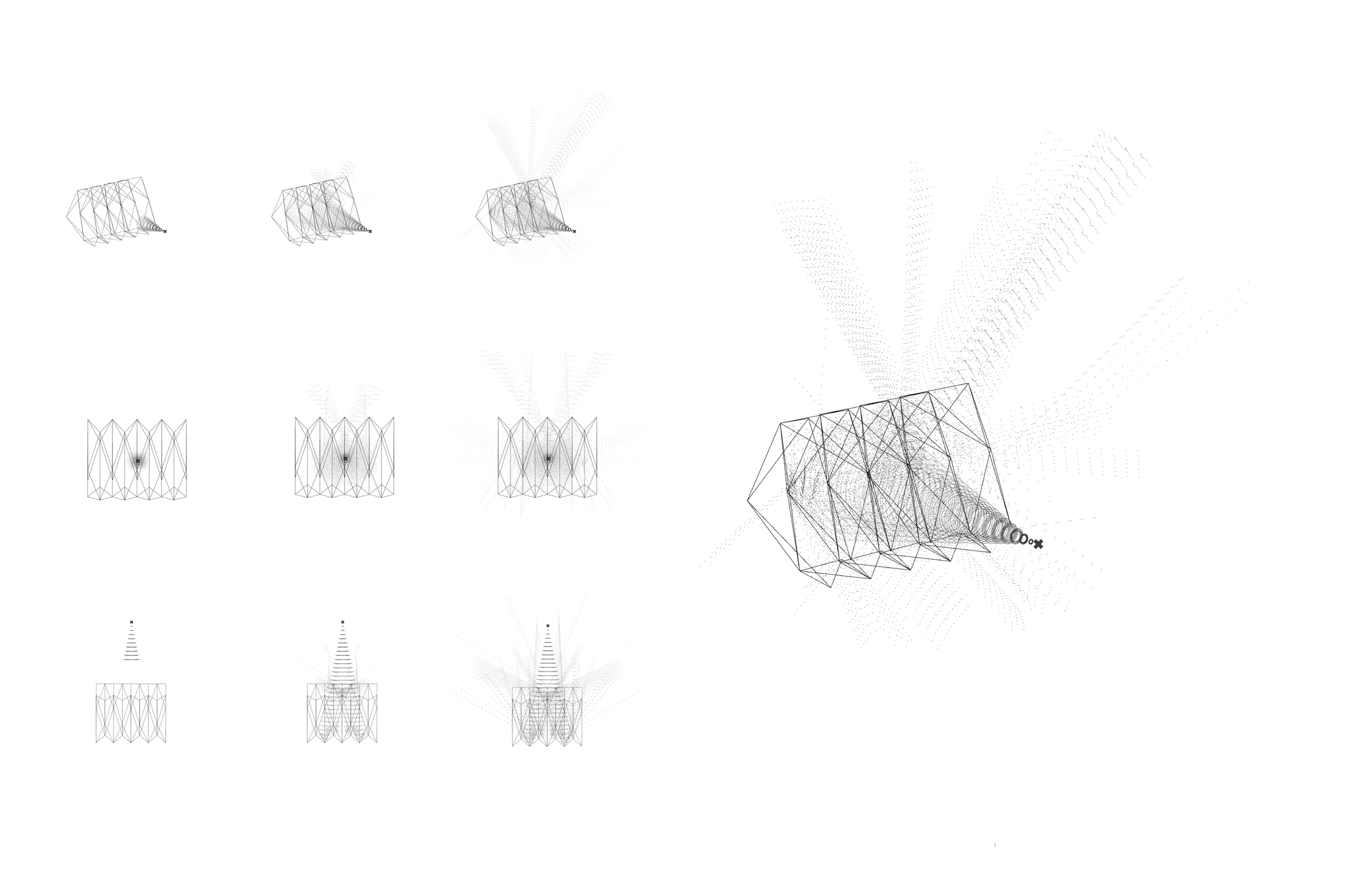

Accordion Pleats :

Links & Attachments: Revit Family_Parallel Accordion Pleats Revit_tutorial Sound_Simulation Fabrication_techniques

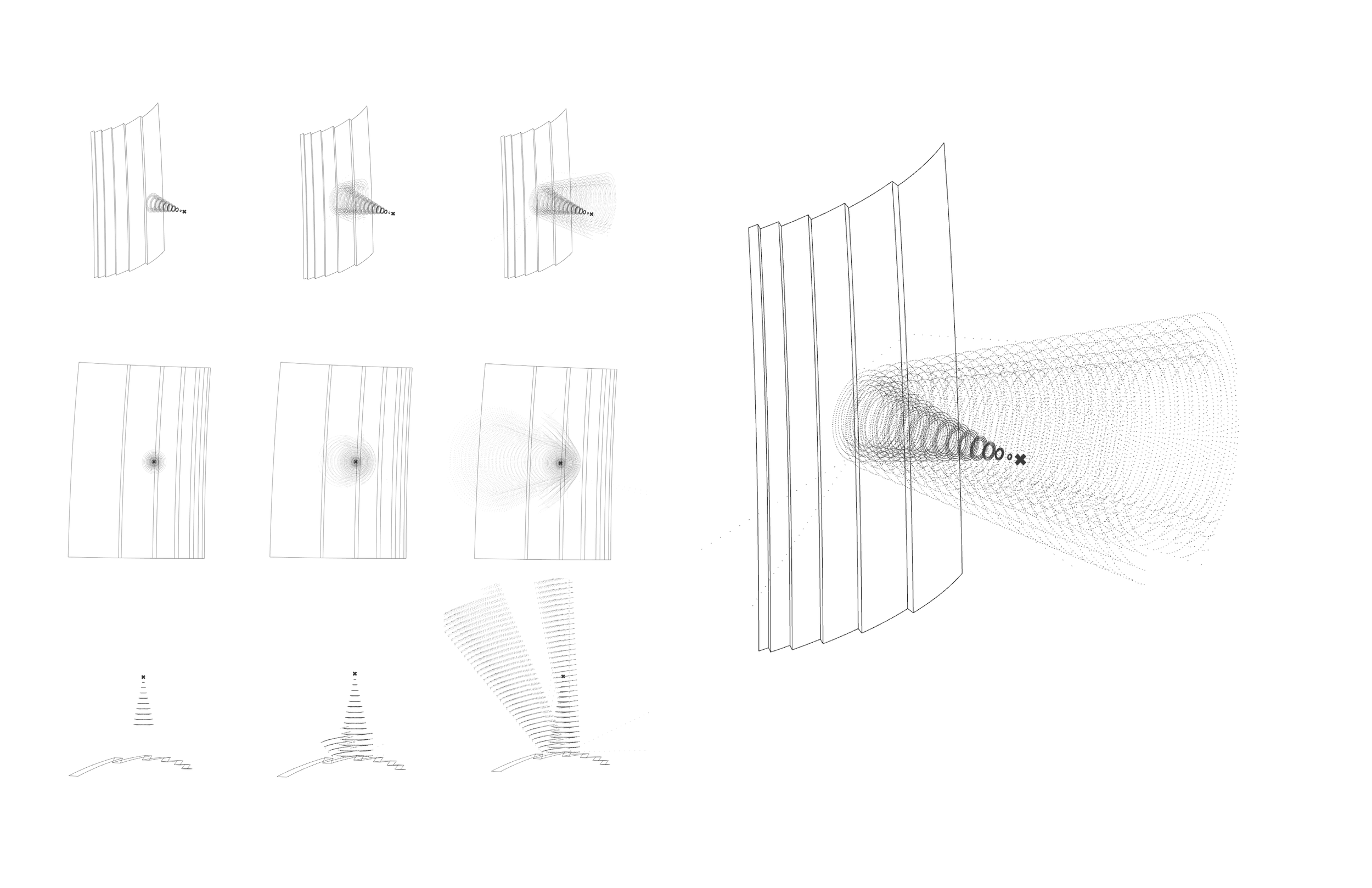

Links & Attachments: Sound_Simulation

Links & Attachments: Sound_Simulation

Links & Attachments: Sound_Simulation

Links & Attachments: Sound_Simulation

Accordion Pleats :

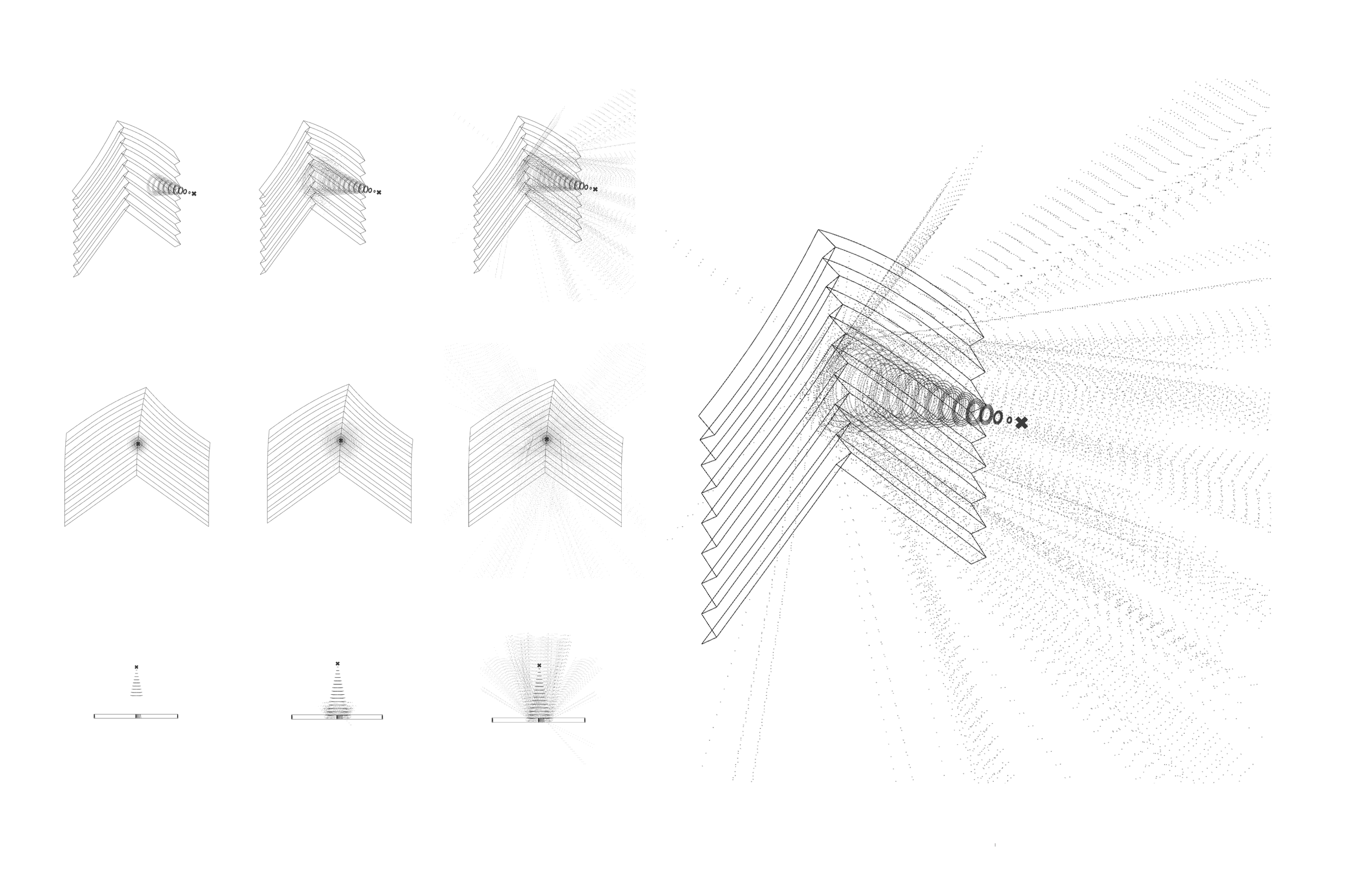

Scattering Coefficient

60° Fold Sound Distribution

120° Fold Sound Distribution

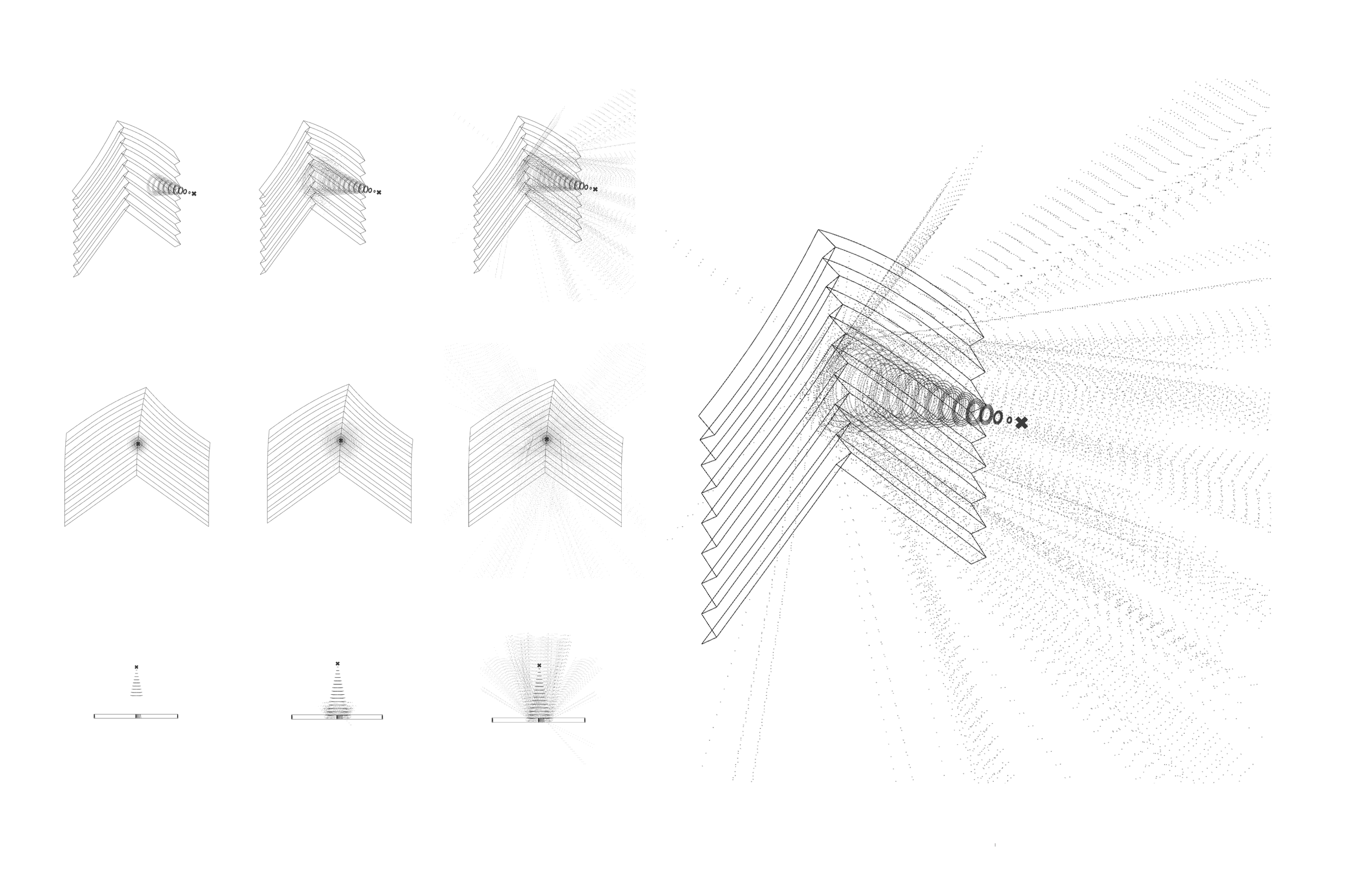

Scattering Coefficient

45° Fold Sound Distribution

75° Fold Sound Distribution

Scattering Coefficient

75° Fold Sound Distribution

45° Fold Sound Distribution

Scattering Coefficient

45° Fold Sound Distribution

90° Fold Sound Distribution

Reverberation Time

Ceiling Condition - Elevation

Ceiling Condition - Perspective

Scattering Coefficient

45° Fold Sound Distribution

75° Fold Sound Distribution

Reverberation Time

Ceiling Condition - Elevation

Ceiling Condition - Perspective

Scattering Coefficient

30° Fold Sound Distribution

60° Fold Sound Distribution

Scattering Coefficient

15° Fold Sound Distribution

35° Fold Sound Distribution

Scattering Coefficient

15° Fold Sound Distribution

60° Fold Sound Distribution

Scattering Coefficient

15° Fold Sound Distribution

60° Fold Sound Distribution

Reverberation Time

Ceiling Condition - Elevation

Ceiling Condition - Perspective

Scattering Coefficient

30° Fold Sound Distribution

60° Fold Sound Distribution

Reverberation Time

Ceiling Condition - Elevation

Ceiling Condition - Perspective

Scattering Coefficient

25° Fold Sound Distribution

55° Fold Sound Distribution

Reverberation Time

Ceiling Condition - Elevation

Ceiling Condition - Perspective

Scattering Coefficient

45° Fold Sound Distribution

90° Fold Sound Distribution

Scattering Coefficient

30° Fold Sound Distribution

75° Fold Sound Distribution

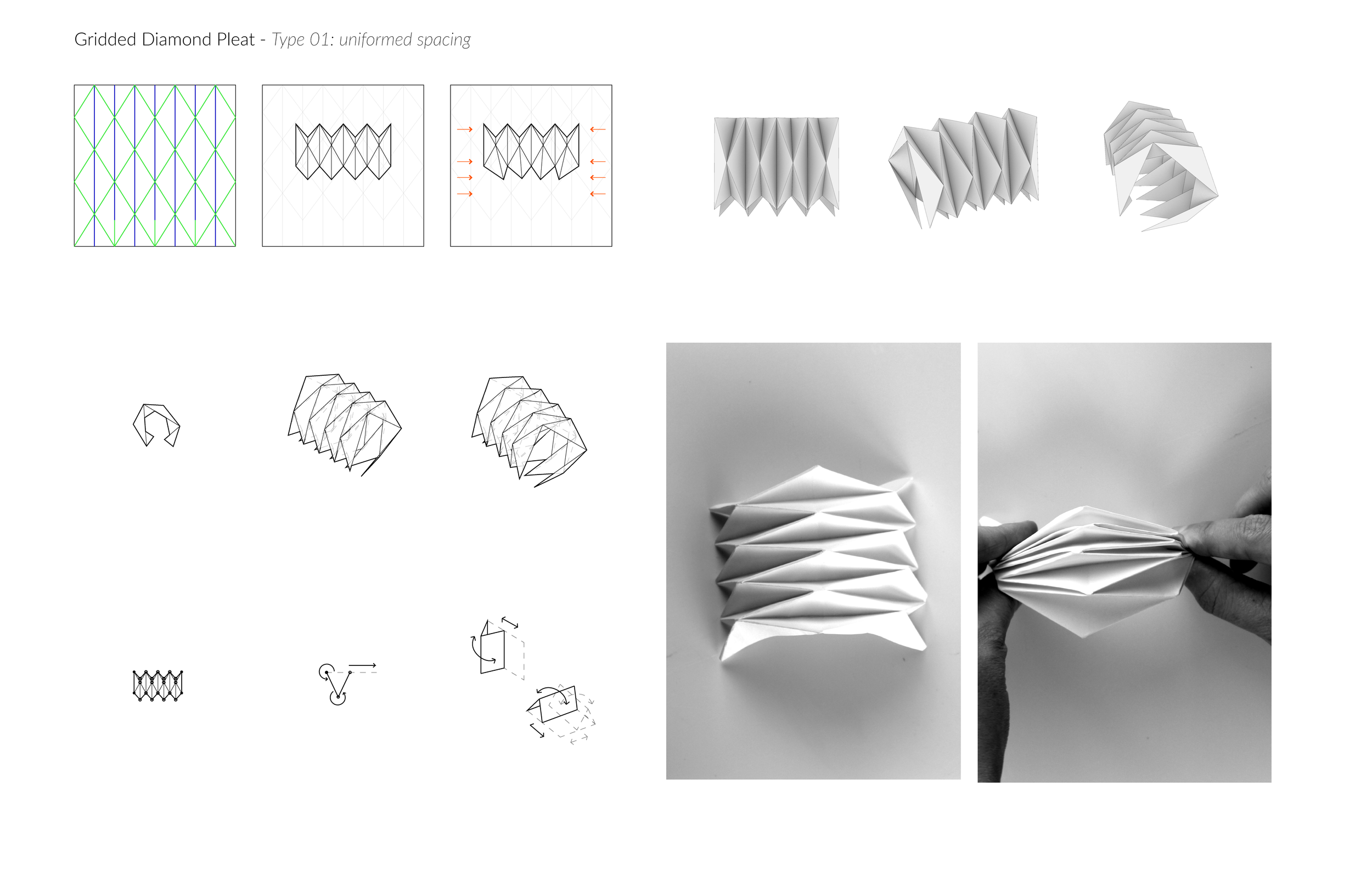

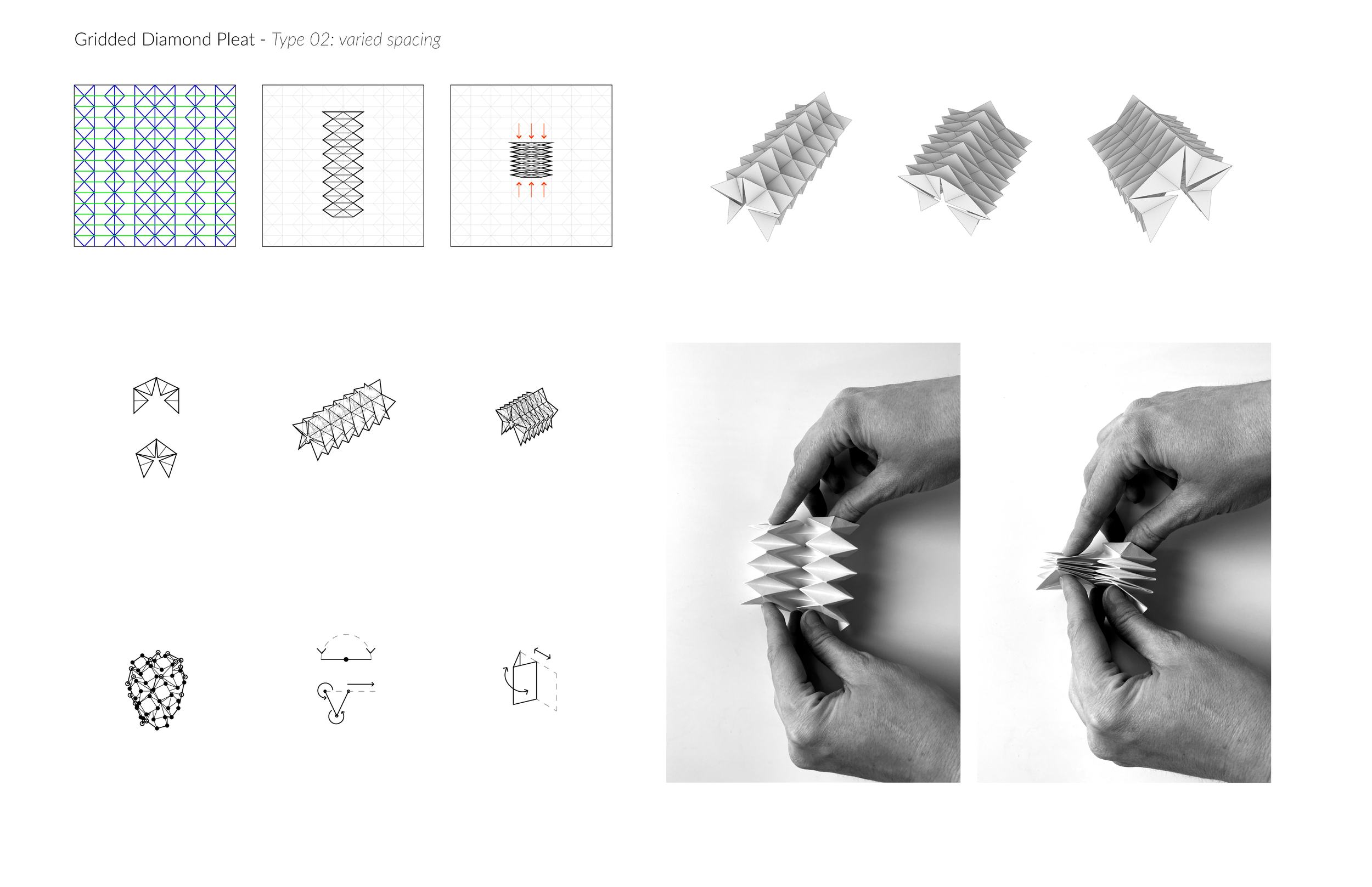

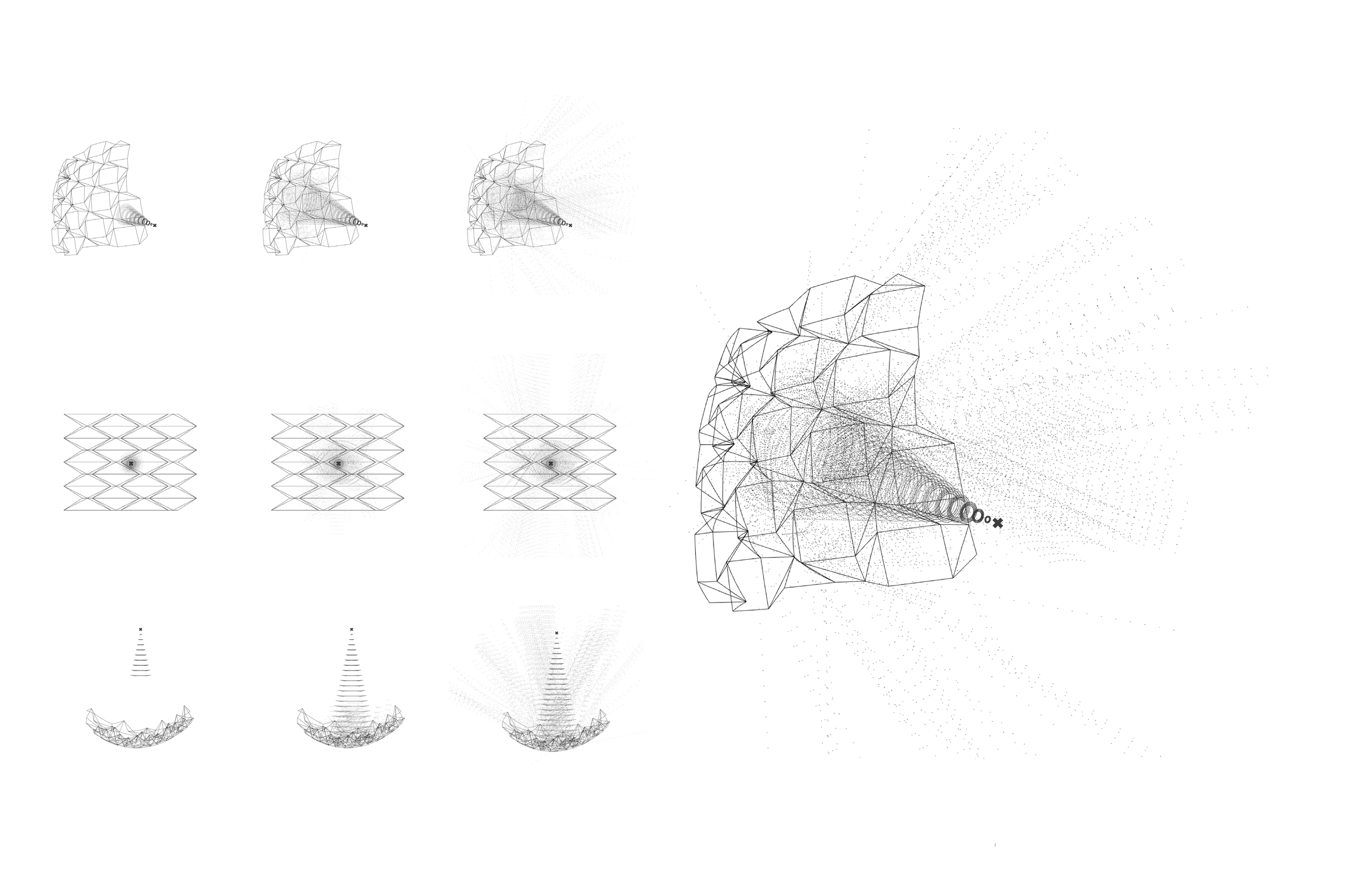

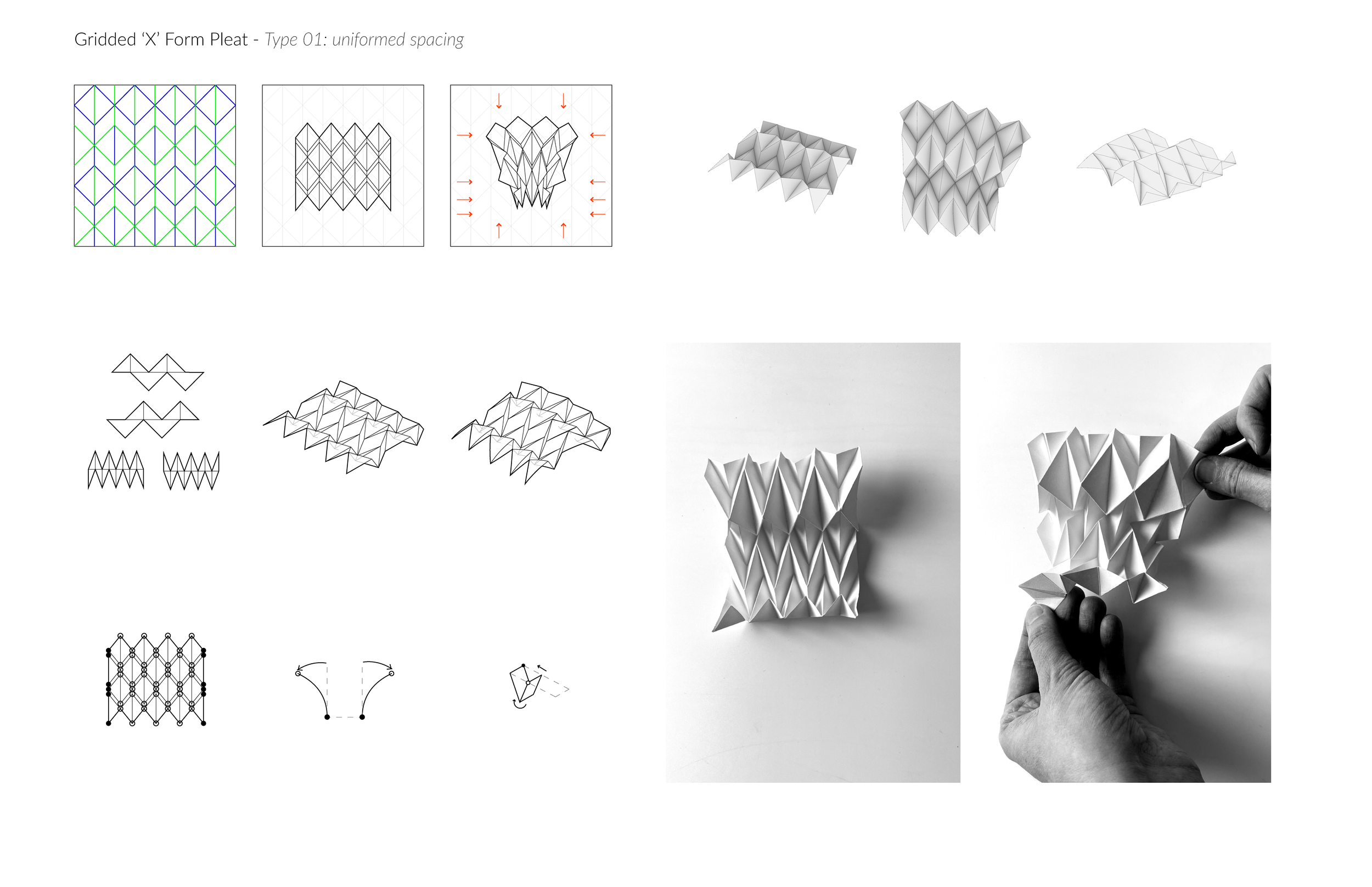

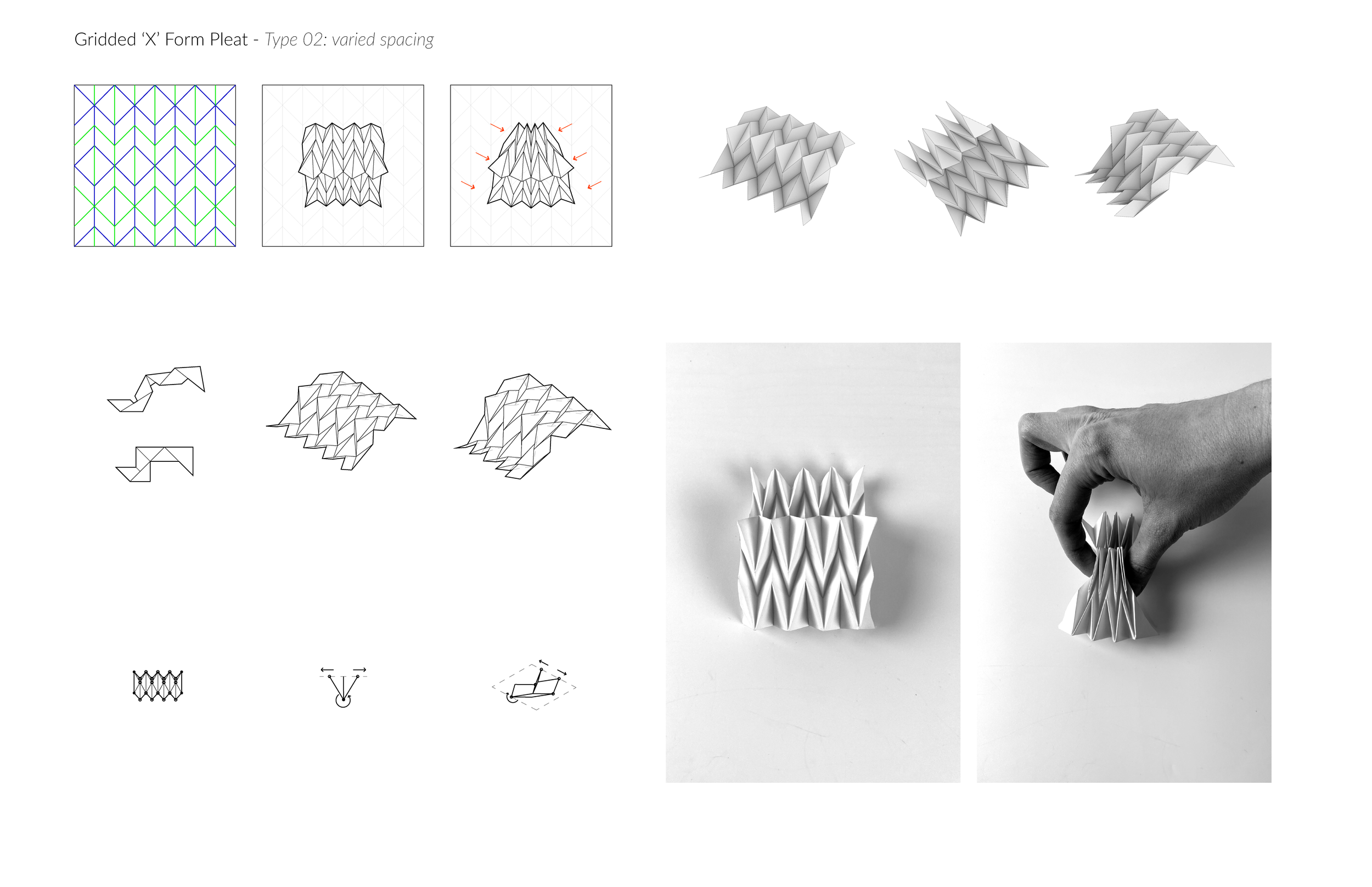

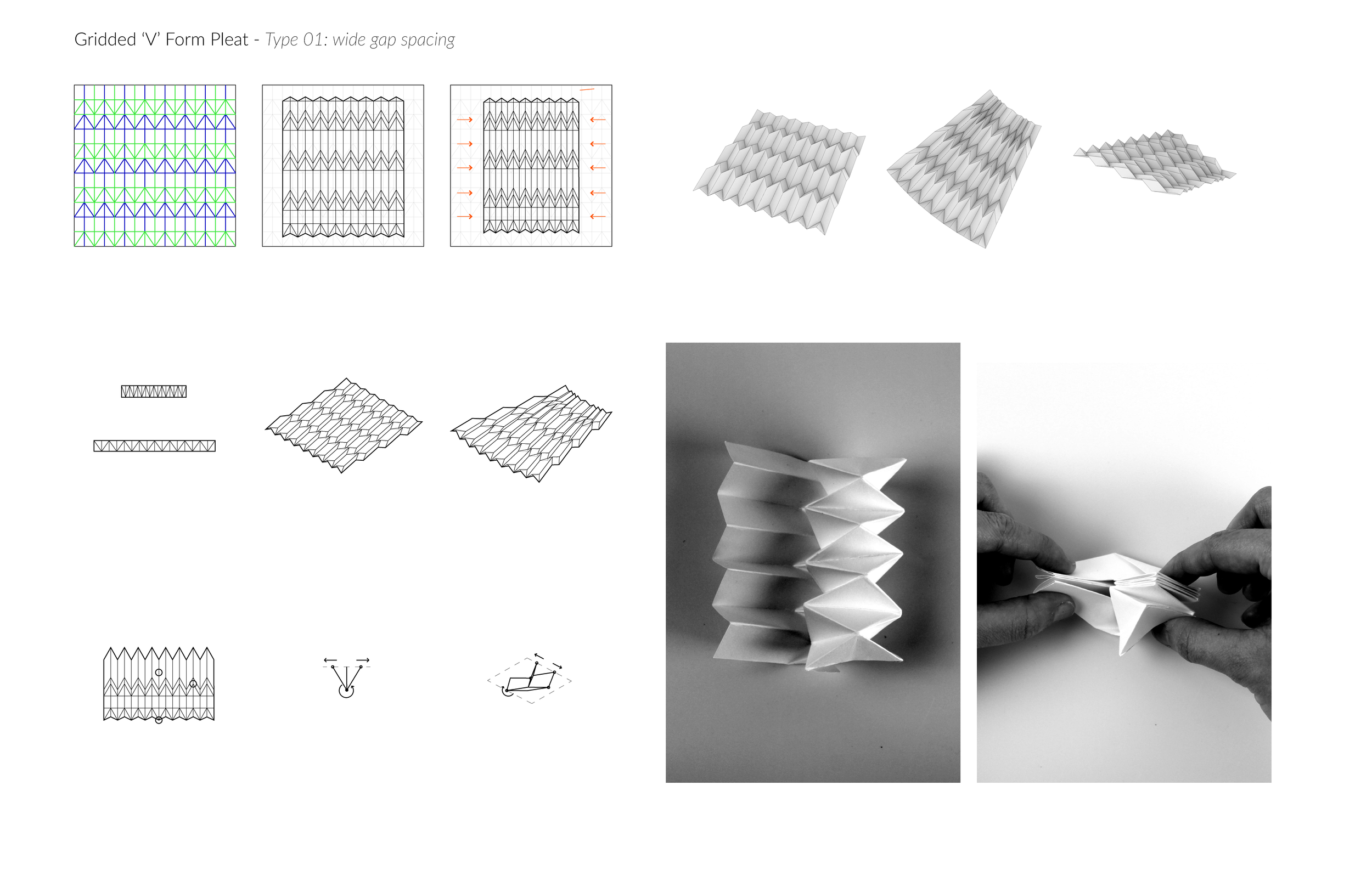

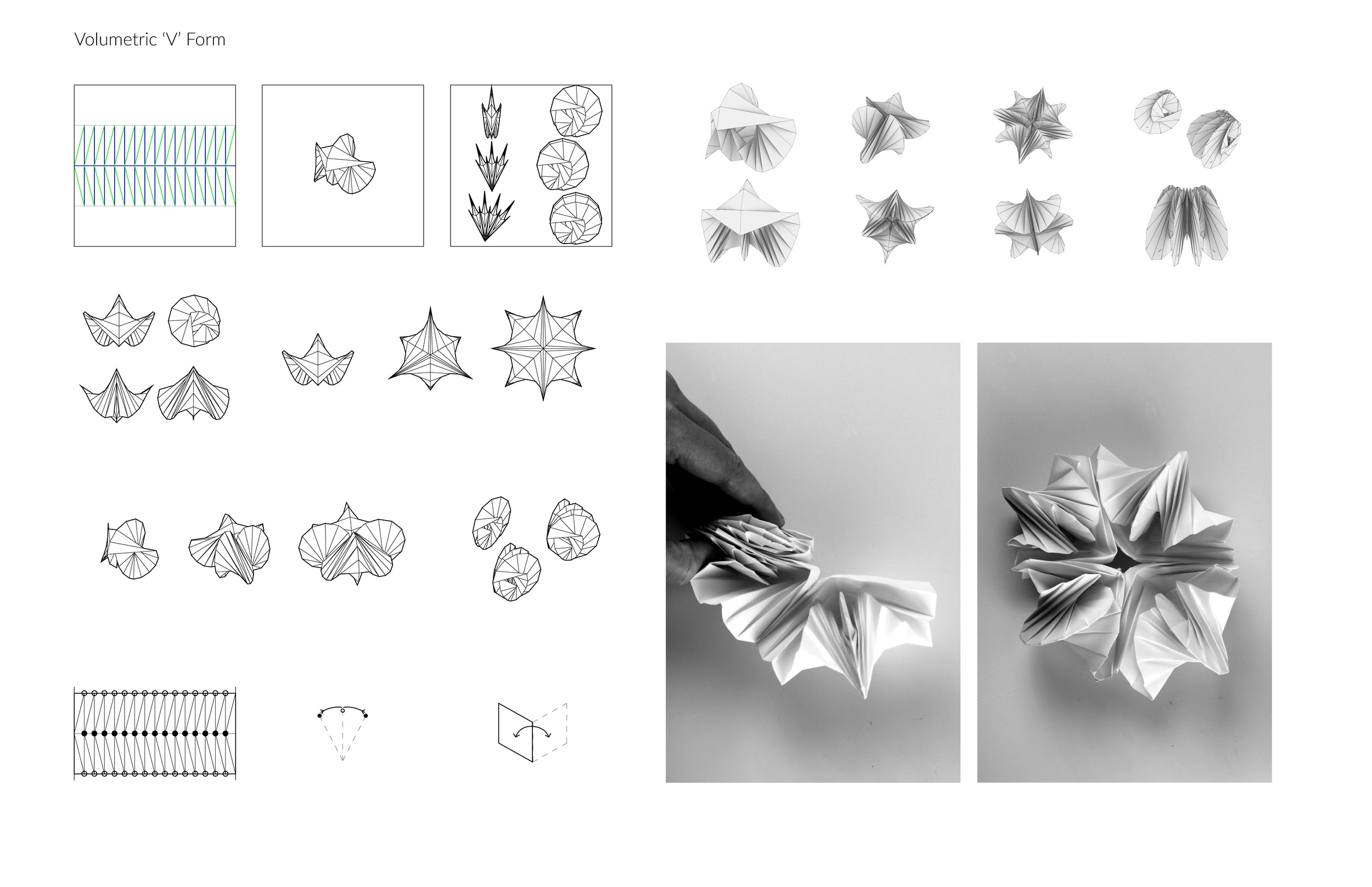

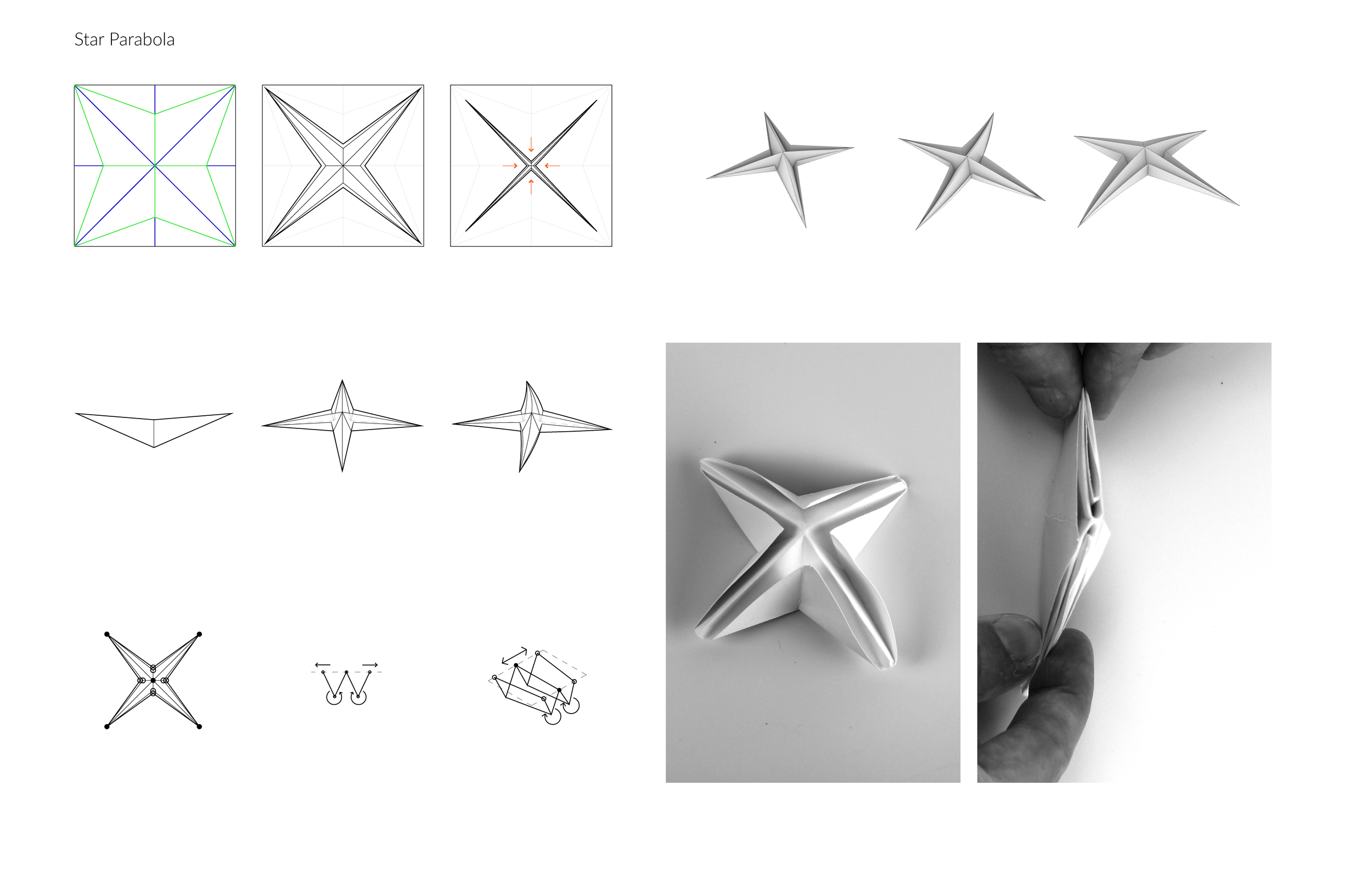

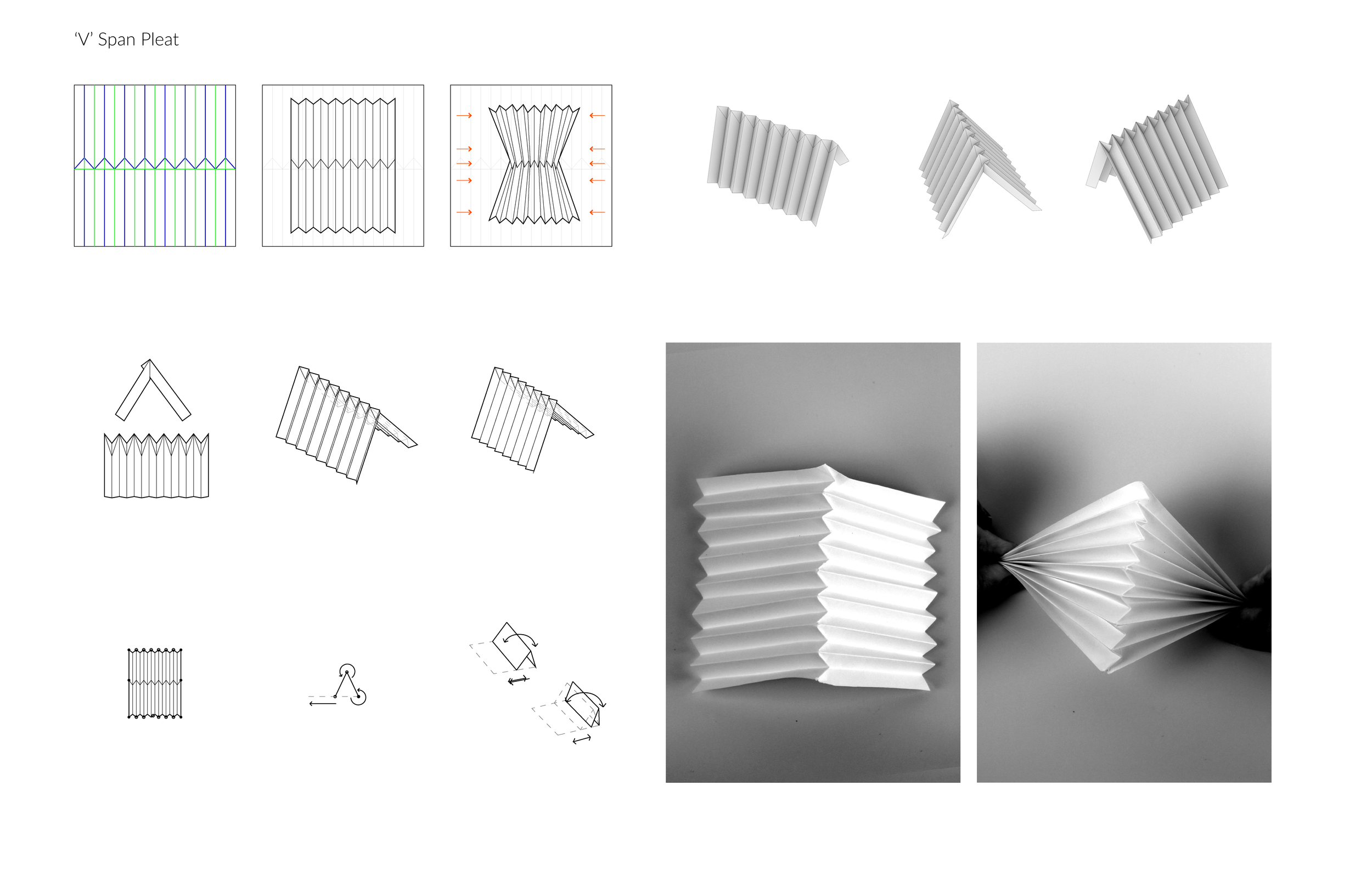

FABRICATION

The material limitations have had an influence on the range of geometric solutions, we have used the material exploration process to inform and identify a range of design solutions. The folding and bending designs include patterns that relate to scoring on the front and back through the process of routing with precision angle bits. This gave control to the angle of the material being removed from the wall board for precise folding.